The Mechanics of Piano Tuning

From the exterior, the workings of the piano appear quite simple – you press a key and a sound is produced. However, the mechanism that allows all this to happen is far more complex than one might realize. This article will talk in detail about the moving parts inside your piano, as well as how to keep them working properly.

The piano was not the first keyboard instrument. It was preceeded by the organ, the clavichord, and the harpsichord. The piano had a major advantage over these instruments, however, which was dynamic control. That is to say, the harder you press the key, the louder the note. In the early 1700′s Bartolomeo Christofori came up with the mechanism which makes this possible know as the “double escapement mechanism”.

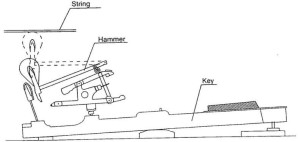

When you push down on the key a hammer strikes the string producing a sound. In a real piano, there are many levers in between. However, imagine for a moment that the key and hammer were connected together as one solid piece. If you pushed down on the key the hammer would hit the string, but with the key still depressed the hammer would continue touching the string and stop it from vibrating. The resulting sound would be a metallic thud. The innovation of the piano mechanism is that the lever which pushes on the hammer slips out of the way at the last second so that the hammer can actually bounce off the string and allow it to vibrate.

The early prototypes of the piano were still a far cry from the modern piano. J.S. Bach lived just long enough to see the first versions of the piano come into being. In fact, there is a famous anecdote in which he visits his son who was court musician for King Frederick of Prussia and the king showed off several new pianos he had just acquired. However, Bach regarded these early prototypes as garish and crude instruments. In Mozart’s time, the piano really came into it’s own as the mechanism was perfected enough for professional usage.

As a piano owner, it is useful to have some knowledge of the workings of the piano, so that you will recognize the importance of having it maintained. Just for the key to hit the hammer properly, there are five moving parts. These parts are the KEY, the WHIPPEN, the JACK, the REPETITION LEVER, and the HAMMER. Each of these moves on a hinge known as a FLANGE. If the wood swells due to high humidity, this flange may become tight and any one of these parts may cease to move. This is why I strongly emphasize a HUMIDITY CONTROL SYSTEM on all pianos. If the flange becomes loose due to low humidity or wear and tear, then the part will move too easily and may even wobble. The result is commonly a clicking sound. If such problems are not prevented by controlling the humidity inside the piano, then your technician will ultimately have to take out the part, remove the pin from the flange, file it with a long needle, then install a new pin. The whole process takes about ten minutes per key. Installing a humidity system can reduce the need for these types of repairs and save you money.

Because there are so many moving parts, each part must be adjusted to precisely the right setting. This procedure is know as regulation. Every five to ten years, your piano should undergo a full regulation to ensure that all the mechanical parts are functioning properly.

Please visit http://lapianotuning.com to keep your piano tuned and functioning properly.